- Phone: 0(533) 488-3330

- Land phone: 0(262) 743-4830

- E-Mail: [email protected]

What Can We Do For You?

Laser cutting

It is a technology that is preferred for cutting iron, bimetal, aluminum, stainless and metal materials and is generally used for industrial production and is also used by schools, SMEs and hobbyists.

Electro Galvanized

Zinc plating is generally the coating of iron or metals with zinc. This coating is the coating of zinc oxide, sodium cyanide, hydroxide chemicals and zinc metal on the parts by electrolysis. This coating ensures that the parts used in the automotive, telecommunication, electrical and construction industries have a longer life against corrosion. In order for the painted materials used in the external sections to have a longer life against corrosion, zinc coating is made under the paint.

Static Powder Coating

The polymerization of the powder paint ensures that the paint adheres to the material during the firing process. The resulting coating exhibits excellent resistance to abrasion, corrosion, chemical influences and impacts.

Machining

The process of removing chips from metals with the help of a cutting tool and bringing them to the desired shape and dimensions is called Machining. As it can be understood from the definition, there is a metal material and a cutting tool in this type of production. The cutting tool tries to remove chips by cutting and the material not to be cut. Depending on the shape and movements of the cutting tool, the material removed from it gives the material, that is, the workpiece, the desired form. Machining can be done according to an existing sample part or according to a drawing called a manufacturing drawing and drawn according to the technical drawing rules. However, in recent years, all productions are made according to the production drawings.

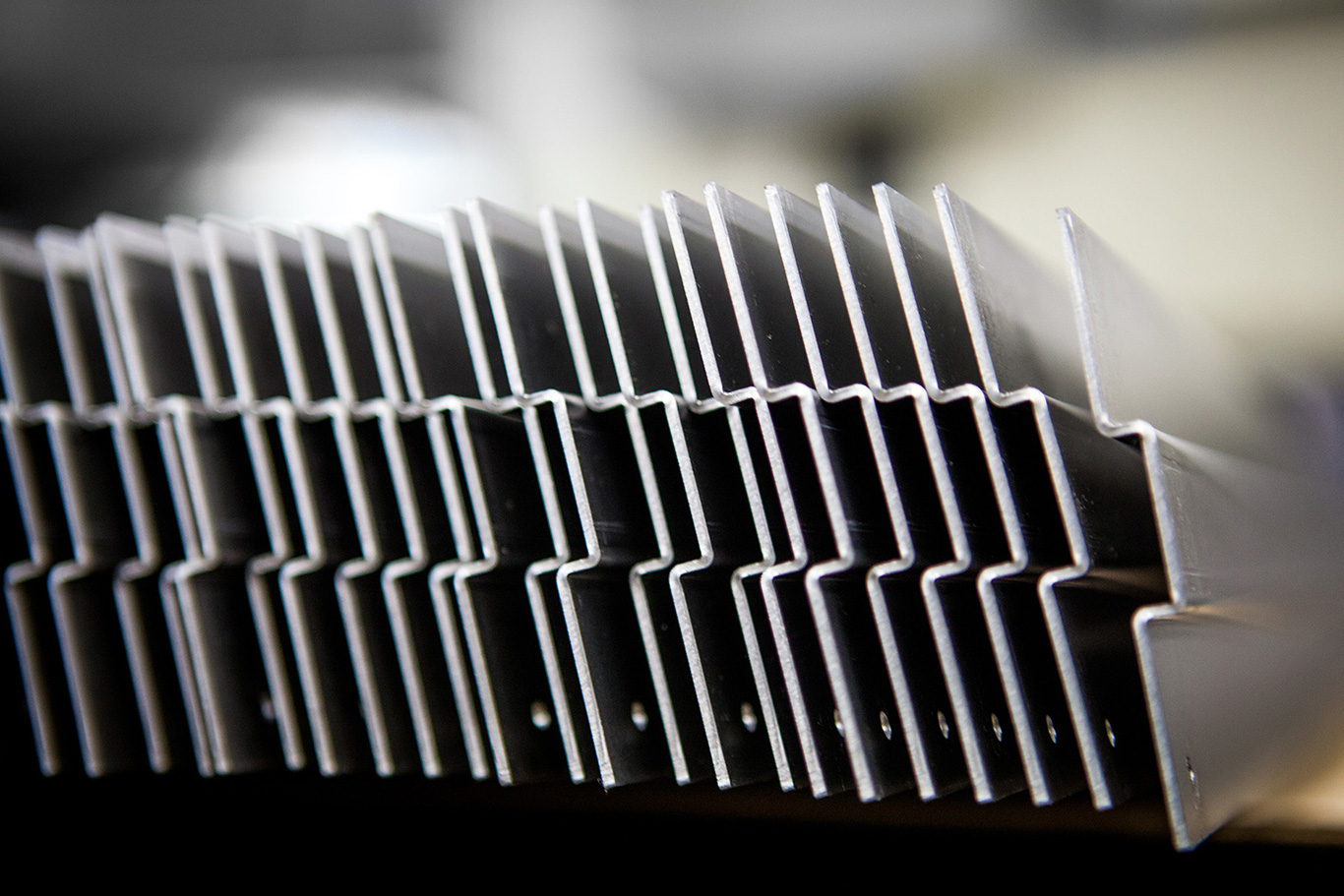

Press Brake

CNC Press Brake is a sheet metal forming machine that bends the sheet metal raw material into the desired form. The more primitive type is called poke. With the press brake bending benches, the sheet metal is pressed between two molds and takes shape. The large mold at the bottom is the female mold, and the upper one is the male mold. There are models in different tonnages and widths. It consists of parts such as upper mold, lower mold, hydraulic axes, CNC control unit. By applying pressure to the female mold of the upper mold with hydraulic force, it compresses the sheet metal and allows bending at different angles.

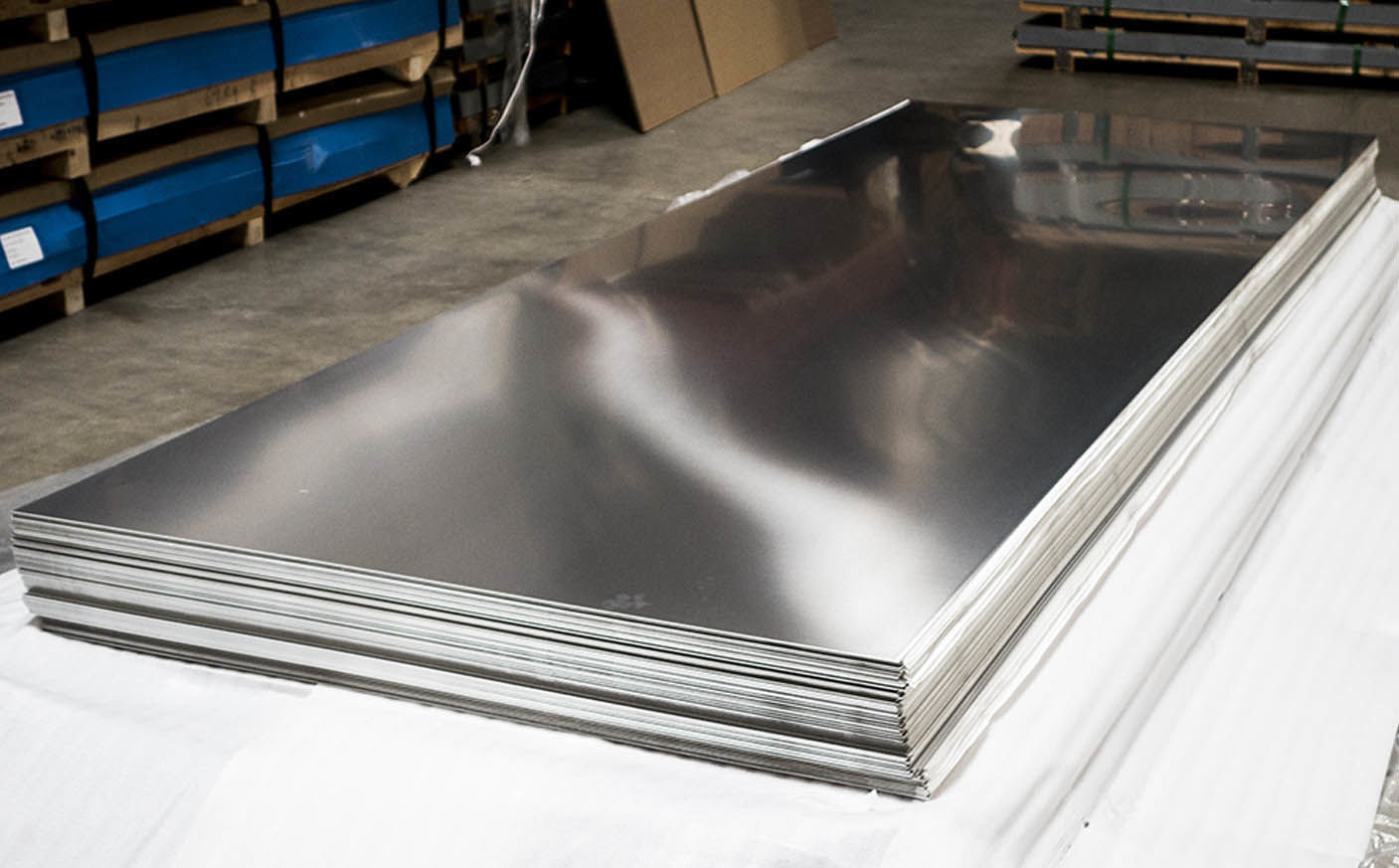

Sac

Sheet metal, especially iron material. It is obtained by passing thick plates between rollers, that is, by rolling. After the first hot rolling, cold rolling is done to obtain a smooth surface. These sheets in different thicknesses are cut within certain standard sizes or in strips. This process is done with two rollers.

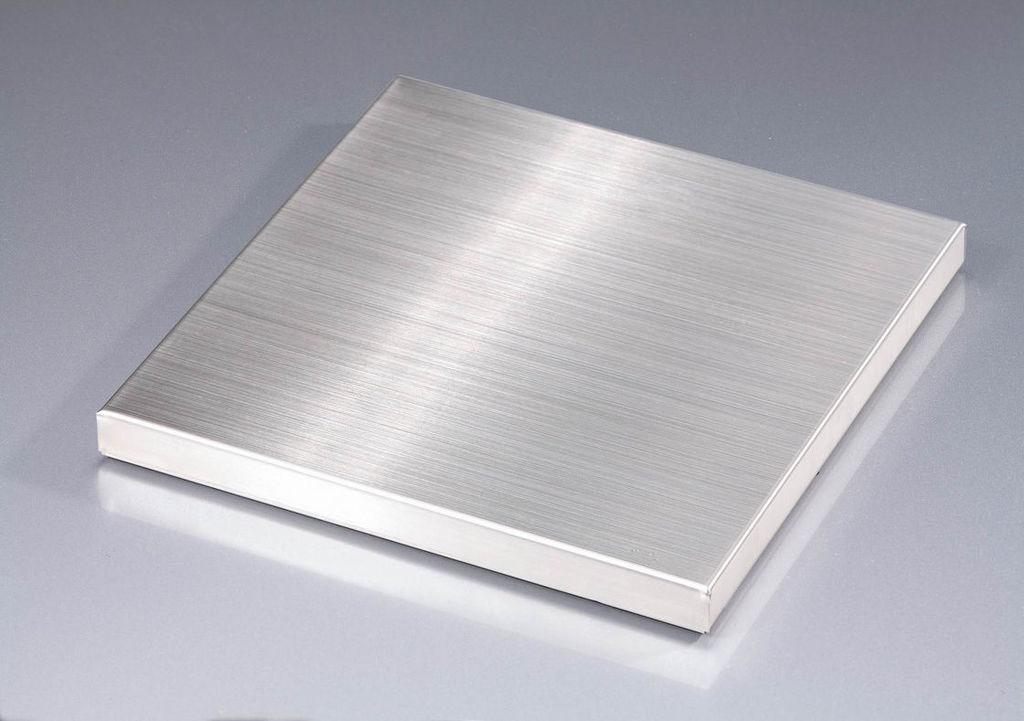

Aluminum

The chemical element aluminium, atomic number 13 and symbol Al. It is a silvery, ductile metal. It is generally found in nature as bauxite ore and is known for its superior resistance to oxidation. The basis of this resistance lies in its passivation property. It is used in the production of millions of different products in many branches of industry and has a very important place in the world economy. Structural components made of aluminum are indispensable for the aerospace industry. It finds wide usage area in transportation and construction industry, which requires lightness and high strength properties.

Sales of Stainless Plates, Pipes and Profiles

Stainless steel is an iron alloy containing 0.5% or more of chromium and 1.2% or less of carbon, and as a result, it forms a self-healing surface layer that provides resistance to corrosion. Pipe is a hollow cylindrical material that is generally used in plumbing construction. It can be manufactured from materials such as ceramic, plastic, metal, depending on the place of use. There are different manufacturing and measurement standards according to the material type and manufacturing methods of the pipes.